ELANTAS is a firm believer that emobility in

connection with renewable energy is the key

for future sustainable mobility and reduction

of global emissions. To support the growth

of emobility globally we support this market

with innovative products which help to operate

electric vehicles safely and enable innovative,

cost efficient solutions through our products.

As a market leader for electrical insulating

and protection materials ELANTAS has over 100

years of experience in the industry.

Wide range of protection and insulation

materials for electric vehicles The ELANTAS product

portfolio offers a broad range of protection and

electrical insulation materials that can be found in

the motor, powertrain, battery and other electronic

components of a vehicle.Different chemistries are

available to provide the product with the best fitting

properties for the application. ELANTAS is also

offering customized solutions for specific application

needs which are developed together with our

customers.

Global Presence for a Global Industry

Our global team of R&D experts and technical

managers are working closely with customer design

engineers and technical staff to solve their issues,

and are supported by the local ELANTAS application

labs in the regions. As a long term supplier to the

automotive industry ELANTAS understands the requirements

and expectations throughout the entire

automotive value chain and is working according to

given standards (IATF 16949), and supplies from our

manufacturing sites in the region on short lead time.

Battery Products:

Protection and longevity

for electric vehicles

Gap Filler

The electrochemical reactions in battery cells for e-cars are highly

dependent on temperature. Therefore it essential to maintain the

battery cells within a healthy temperature window of operation.

In addition, minimizing the temperature differences within the module

and pack is crucial to ensuring longevity. Unwanted side reactions

in local hot spots within the pack decrease cell capacity and result in

continuing loss of overall capacity. Management of the heat flow, for

example with the help of ELANTAS gap fillers of silicone or polyurethane

chemistry is therefore critical.

Thermal Adhesives

In eMobility applications, the increasing thermal management challenges

require heat dissipation across bondlines.

• Adhesives are a proven light-weight, effective bonding solution.

• They must reliably fulfill fixation and provide a path for effective

heat transfer.

Examples for thermal adhesives applications are the fixation of cooling

elements or heat sinks to the heat source and the cell to cell fixation.

For such applications, ELANTAS products are highly recommended.

They are suitable for most substrates and can be machine applied or

dispensed manually, if preferred.

Thermal Grease

In eMobility applications, the increasing thermal management challenges

require heat dissipation across bondlines.

• Greases are a proven effective heat transfer compound.

• Easy to apply one component non-curing property ensures ideal

thermal contact.

The battery systems in electric cars are highly relevant to

the success of electromobility.

A vehicle’s market price, performance while driving and

charging, longevity and sustained range over its lifetime,

and safety are just a few factors that the battery essentially

determines.

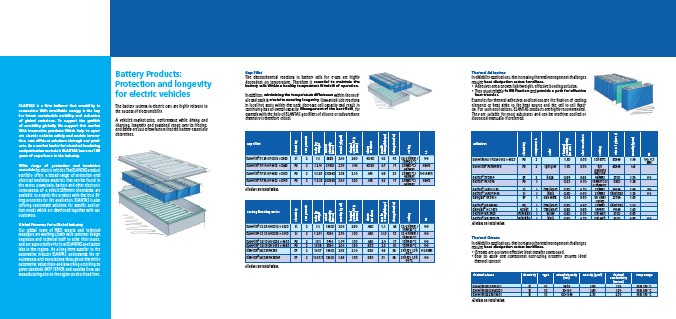

Gap Fillers

Chemistry

Components

Ratio by

Weight

Mixed

Viscosity

mPas

Density g/ml

Thermal

Conductivity

W/mK

Shore

Hardness

Tensile

Strength Mpa

Elongation %

Curing

UL

ELAN-tim® FS 26 OP 0012 + 0023 Si 2 1:1 paste 3,00 2,60 00 60 0,2 45 12 – 24h@RT /

1h@120 °C

V-0

ELAN-tim® FP 14 AP 0072 + 0083 PU 2 1:2,41 24500 2,50 1,40 00 80 0,7 17 2h@90 °C /

48h@RT

HB/V2

ELAN-tim® FP 21 AP 0092 + 0103 PU 2 1:1,95 210000 2,78 2,10 A70 0,9 25 2h@90 °C /

48h@RT

V-0,6 mm

ELAN-tim® FP 30 AP 0032 + 0043 PU 2 1:2,18 200000 3,00 3,20 A78 0,2 17 2h@90 °C /

48h@RT

HB/V2

Adhesives

Chemistry

Components

Color

Thermal

Conductivity

W/mK

Shore Hardness

Curing

Viscosity mPas

Density g/ml

UL

ELAN-tim AU 17 DM 0012 + 0023 PU 2 1,70 D 53 15h 60°C 90000 1,40 V-0, 4,5

mm

ELAN-tron® PU79/PH79 PU 2 light gray 1.70 D 50 RT/

moderate

heat cure

80000 1,8

Bectron® EP 5504 EP 2 beige 0,96 D 82 48h@RT 2700 1,70 V-0

Bectron® PK 4340 PU 1 0,25 A 70 1h@80°C or

0,5h@90°C

9500 1,28

Bectron® SA70 L1‑30 Si 1 translucent 0,20 A 30 24h@RT 44000 1,06 HB

Bectron® SA70 P 9-60 Si 1 black 0,60 A 60 24h@RT Thixotropic 1,30 V-0

Elan‑glue® EP 5611 EP 1 pale white 0,46 D 90 UV / heat

curing

32500 1,63

Bectron® AR 4826N PU 1 translucent 0,20 A 67 24h@RT Thixotropic 1,10

Elan‑glue® AC 1650 Acrylat 1 translucent 0,20 D 85 UV@RT 14000 1,05

Bectron® MR 3405 Polyolefin 1 yellow 0,20 A 30 Hot Melt 2100 0,85

Bectron® MR 3405 FR Polyolefin 1 black 0,20 A 35 Hot Melt 2000 0,85 V-0

Thermal Grease Chemistry Type Mixed Viscosity

Pas

Density g/ml Thermal

Conductivity

W/mK

Temp Range

ELAN-tim GS12NP0021 Si 1K paste 1,95 1,20 max 150 °C

ELAN-tim GS12NM0021 Si 1K 30-100 1,85 1,30 max 200 °C

ELAN-tim GS25NH0051 Si 1K 100-1000 2,50 2,50 max 150 °C

Casting & Potting Resins

Chemistry

Components

Ratio by

Weight

Mixed

Viscosity

mPas

Density g/ml

Thermal

Conductivity

W/mK

Shore

Hardness

Tensile

Strength Mpa

Elongation %

Curing

UL

ELAN-tim® CS 26 AV 0012 + 0023 Si 2 1:1 10000 3,00 2,60 A60 1,1 18 12 – 24h@RT /

1h@120 °C

V-0

ELAN-tim® CS 15 AV 0032 + 0043 Si 2 1:2,41 4000 2,70 1,50 A50 1,15 75 12 – 24h@RT /

1h@120 °C

V-0

ELAN-tim® CU 13 AV 0052 + 0063 PU 2 10:1 5700 1,74 1,30 A90 2,4 17 15h@60 °C V-0

ELAN-tim® CU 16 DV 0072 + 0083 PU 2 100:8 9000 2,00 1,60 D35 2,5 10 15h@60 °C V-0

Elan-tron® MC724/W365 EP 2 100:7 10000 2,42 2,10 D90 68 na 24h RT / 15 h

60 °C

V-0,6mm

Elan-tron® MC336/W360NF EP 2 100:7,5 12000 1,88 1,55 D85 51 na 24h RT / 15 h

60 °C

V-0

All values are typical values.

All values are typical values.

All values are typical values.

All values are typical values.