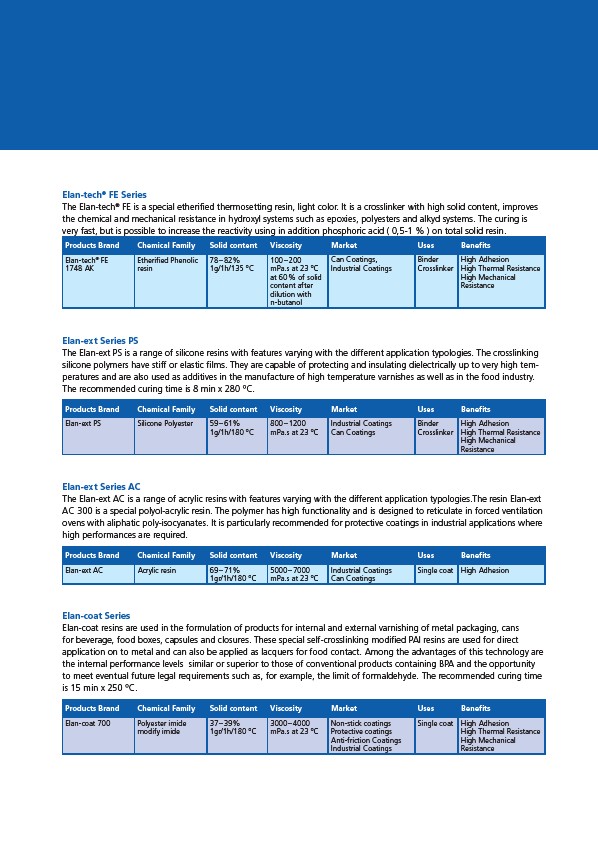

Elan-tech® FE Series

The Elan-tech® FE is a special etherified thermosetting resin, light color. It is a crosslinker with high solid content, improves

the chemical and mechanical resistance in hydroxyl systems such as epoxies, polyesters and alkyd systems. The curing is

very fast, but is possible to increase the reactivity using in addition phosphoric acid ( 0,5-1 % ) on total solid resin.

Products Brand Chemical Family Solid content Viscosity Market Uses Benefits

Elan-tech® FE

Etherified Phenolic

78 – 82%

1748 AK

resin

1g/1h/135 °C

100 – 200

mPa.s at 23 °C

at 60 % of solid

content after

dilution with

n-butanol

Can Coatings,

Industrial Coatings

Binder

Crosslinker

High Adhesion

High Thermal Resistance

High Mechanical

Resistance

Elan-ext Series PS

The Elan-ext PS is a range of silicone resins with features varying with the different application typologies. The crosslinking

silicone polymers have stiff or elastic films. They are capable of protecting and insulating dielectrically up to very high temperatures

and are also used as additives in the manufacture of high temperature varnishes as well as in the food industry.

The recommended curing time is 8 min x 280 °C.

Products Brand Chemical Family Solid content Viscosity Market Uses Benefits

Elan-ext PS Silicone Polyester 59 – 61%

1g/1h/180 °C

800 – 1200

mPa.s at 23 °C

Industrial Coatings

Can Coatings

Binder

Crosslinker

High Adhesion

High Thermal Resistance

High Mechanical

Resistance

Elan-ext Series AC

The Elan-ext AC is a range of acrylic resins with features varying with the different application typologies.The resin Elan-ext

AC 300 is a special polyol-acrylic resin. The polymer has high functionality and is designed to reticulate in forced ventilation

ovens with aliphatic poly-isocyanates. It is particularly recommended for protective coatings in industrial applications where

high performances are required.

Products Brand Chemical Family Solid content Viscosity Market Uses Benefits

Elan-ext AC Acrylic resin 69 – 71%

1gr/1h/180 °C

5000 – 7000

mPa.s at 23 °C

Industrial Coatings

Can Coatings

Single coat High Adhesion

Elan-coat Series

Elan-coat resins are used in the formulation of products for internal and external varnishing of metal packaging, cans

for beverage, food boxes, capsules and closures. These special self-crosslinking modified PAI resins are used for direct

application on to metal and can also be applied as lacquers for food contact. Among the advantages of this technology are

the internal performance levels similar or superior to those of conventional products containing BPA and the opportunity

to meet eventual future legal requirements such as, for example, the limit of formaldehyde. The recommended curing time

is 15 min x 250 °C.

Products Brand Chemical Family Solid content Viscosity Market Uses Benefits

Elan-coat 700 Polyester imide

modify imide

37 – 39%

1gr/1h/180 °C

3000 – 4000

mPa.s at 23 °C

Non-stick coatings

Protective coatings

Anti-friction Coatings

Industrial Coatings

Single coat High Adhesion

High Thermal Resistance

High Mechanical

Resistance