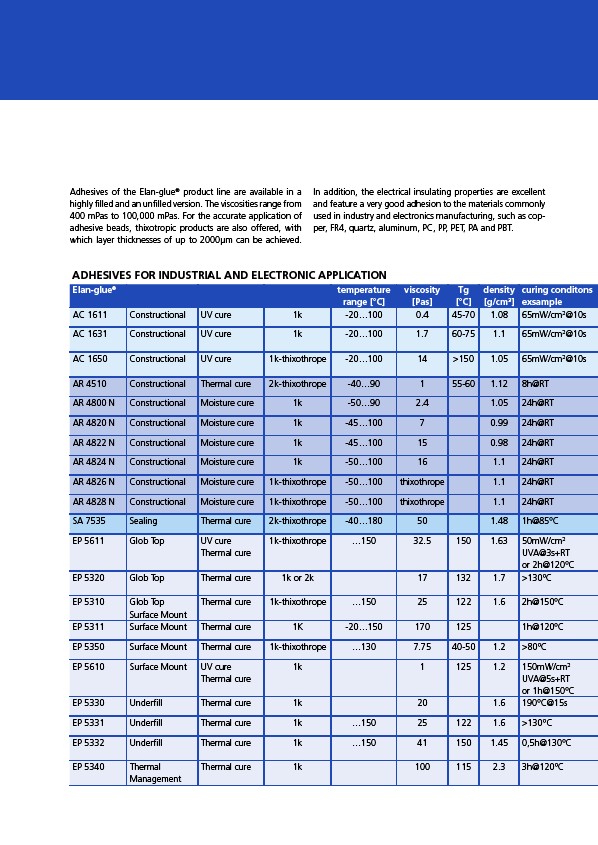

Adhesives of the Elan-glue® product line are available in a

highly filled and an unfilled version. The viscosities range from

400 mPas to 100,000 mPas. For the accurate application of

adhesive beads, thixotropic products are also offered, with

which layer thicknesses of up to 2000μm can be achieved.

In addition, the electrical insulating properties are excellent

and feature a very good adhesion to the materials commonly

used in industry and electronics manufacturing, such as copper,

FR4, quartz, aluminum, PC, PP, PET, PA and PBT.

ADHESIVES FOR INDUSTRIAL AND ELECTRONIC APPLICATION

Elan-glue® temperature

range °C

viscosity

Pas

Tg

°C

density

g/cm³

curing conditons

exsample

AC 1611 Constructional UV cure 1k -20…100 0.4 45-70 1.08 65mW/cm²@10s AC 1631 Constructional UV cure 1k -20…100 1.7 60-75 1.1 65mW/cm²@10s AC 1650 Constructional UV cure 1k-thixothrope -20…100 14 >150 1.05 65mW/cm²@10s AR 4510 Constructional Thermal cure 2k-thixothrope -40…90 1 55-60 1.12 8h@RT AR 4800 N Constructional Moisture cure 1k -50…90 2.4 1.05 24h@RT

AR 4820 N Constructional Moisture cure 1k -45…100 7 0.99 24h@RT AR 4822 N Constructional Moisture cure 1k -45…100 15 0.98 24h@RT AR 4824 N Constructional Moisture cure 1k -50…100 16 1.1 24h@RT AR 4826 N Constructional Moisture cure 1k-thixothrope -50…100 thixothrope 1.1 24h@RT AR 4828 N Constructional Moisture cure 1k-thixothrope -50…100 thixothrope 1.1 24h@RT SA 7535 Sealing Thermal cure 2k-thixothrope -40…180 50 1.48 1h@85°C EP 5611 Glob Top UV cure

Thermal cure

1k-thixothrope …150 32.5 150 1.63 50mW/cm²

UVA@3s+RT

or 2h@120°C

EP 5320 Glob Top Thermal cure 1k or 2k 17 132 1.7 >130°C EP 5310 Glob Top

Thermal cure 1k-thixothrope …150 25 122 1.6 2h@150°C Surface Mount

EP 5311 Surface Mount Thermal cure 1K -20…150 170 125 1h@120°C EP 5350 Surface Mount Thermal cure 1k-thixothrope …130 7.75 40-50 1.2 >80°C EP 5610 Surface Mount UV cure

Thermal cure

1k 1 125 1.2 150mW/cm²

UVA@5s+RT

or 1h@150°C

EP 5330 Underfill Thermal cure 1k 20 1.6 190°C@15s EP 5331 Underfill Thermal cure 1k …150 25 122 1.6 >130°C EP 5332 Underfill Thermal cure 1k …150 41 150 1.45 0,5h@130°C EP 5340 Thermal

Management

Thermal cure 1k 100 115 2.3 3h@120°C